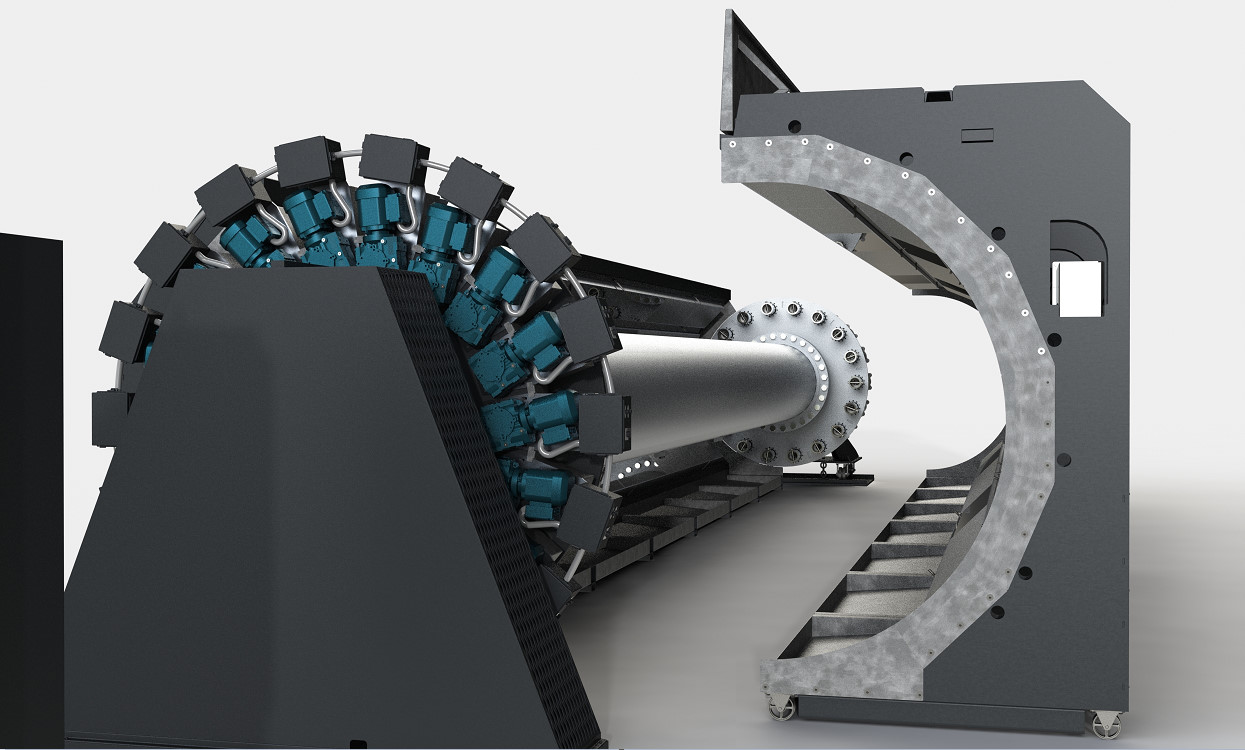

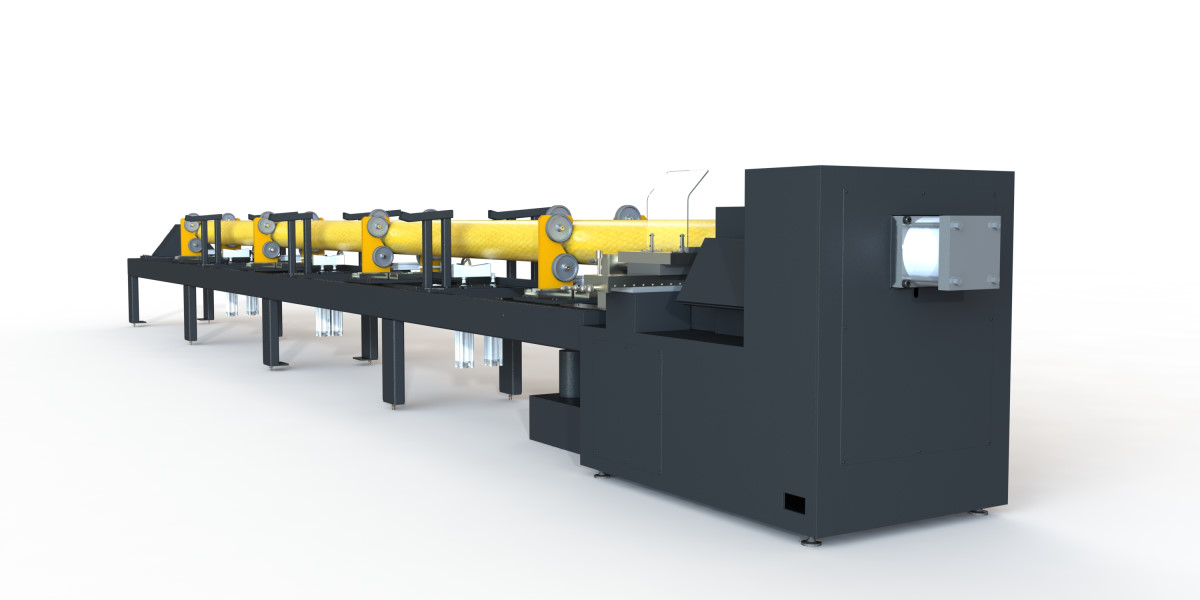

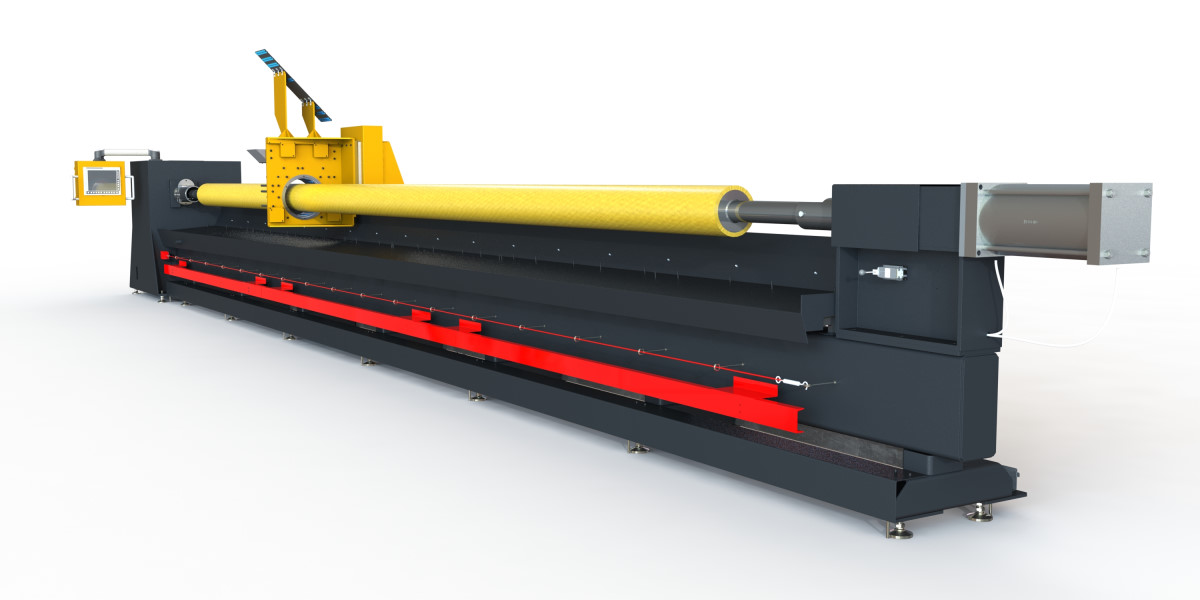

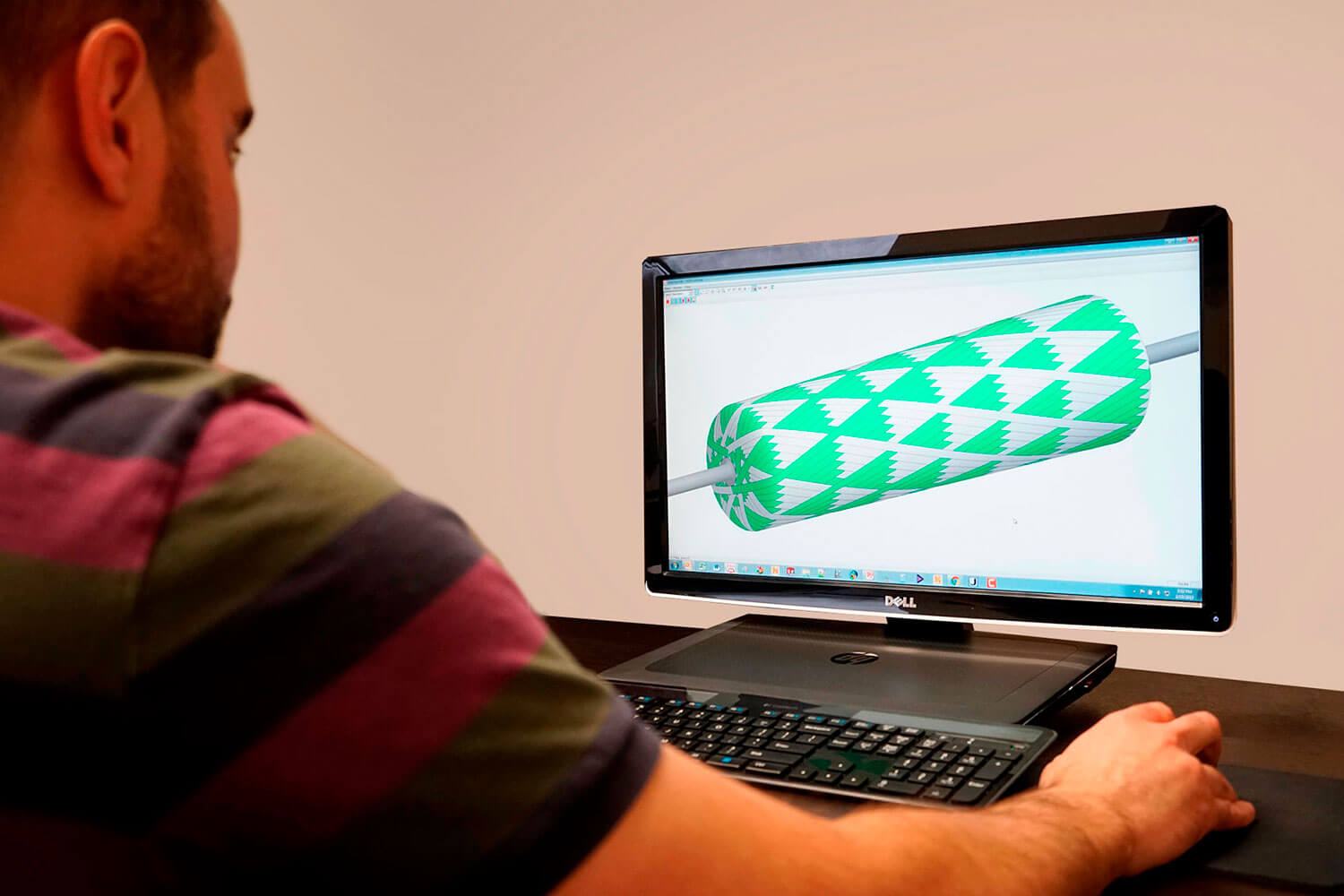

Engineering Technology Corporation’s team of engineers, material specialists, and process technicians allows manufacturing of customized filament winding machinery, production lines, automated work cells, and other auxiliary equipment for a complete production cycle. The company develops and supplies all kinds of equipment for filament winding and provides consulting, process integration, automation, installation, training, and maintenance support.

Contact us to discuss your goals for filament winding and how we can apply our expert capabilities to create the best solution to suit your filament winding needs.